innovative carrier system for multiplex applications.

As an innovative carrier system Syndisk is developed for customized requirements ensuring maximum process modularity, flexibility, efficiency and sustainability within one system.

EXPLORE THE SYSTEM

PATENTED SYSTEM.

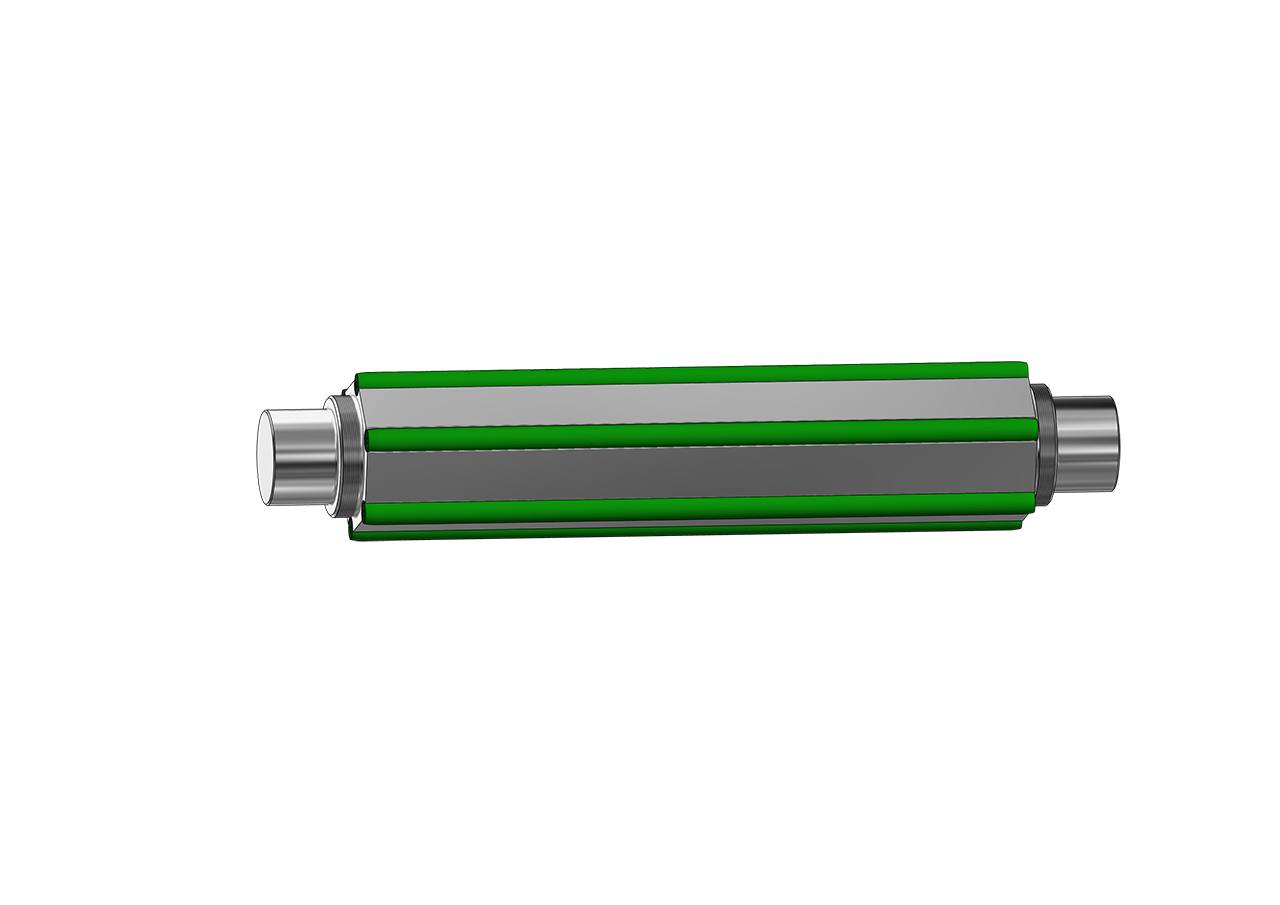

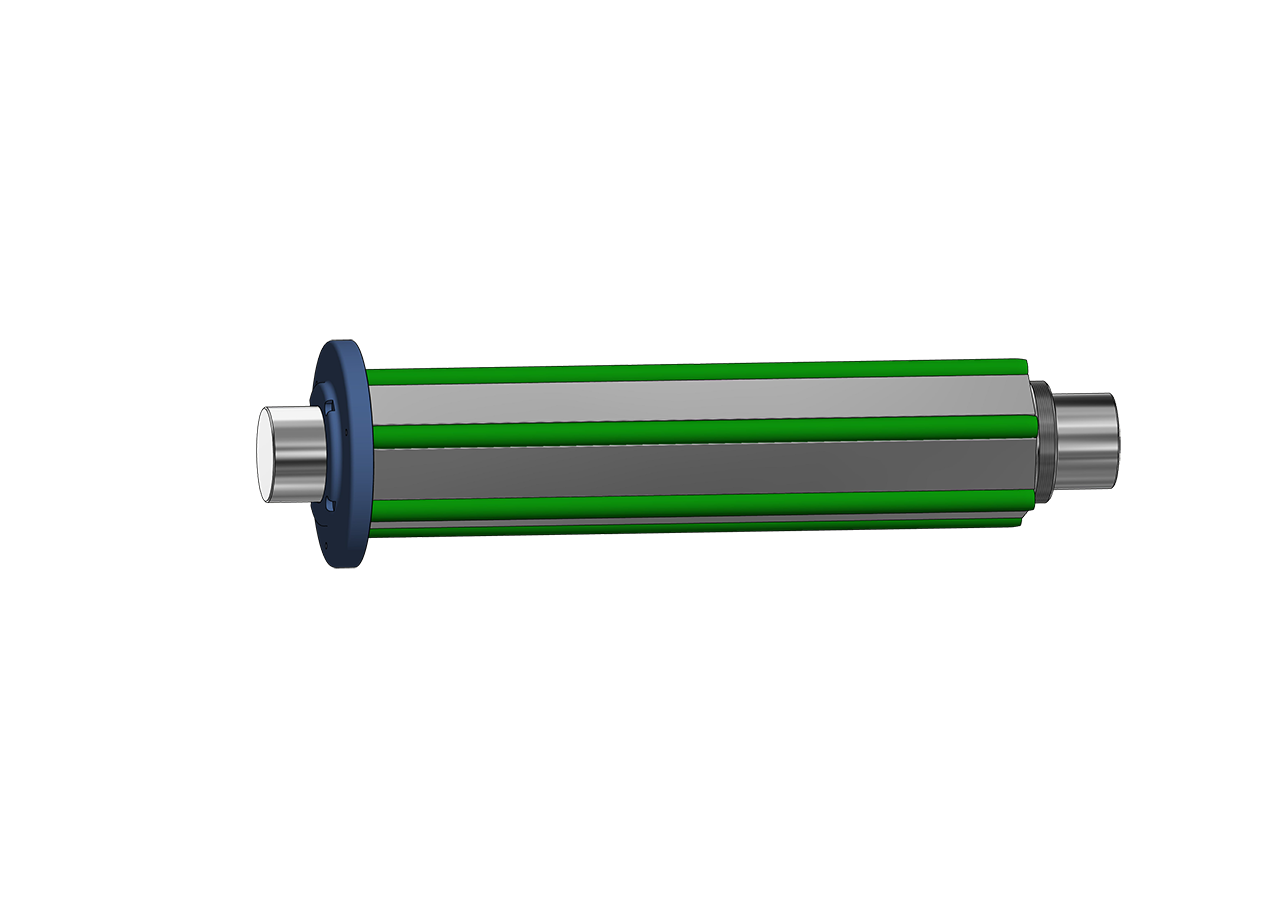

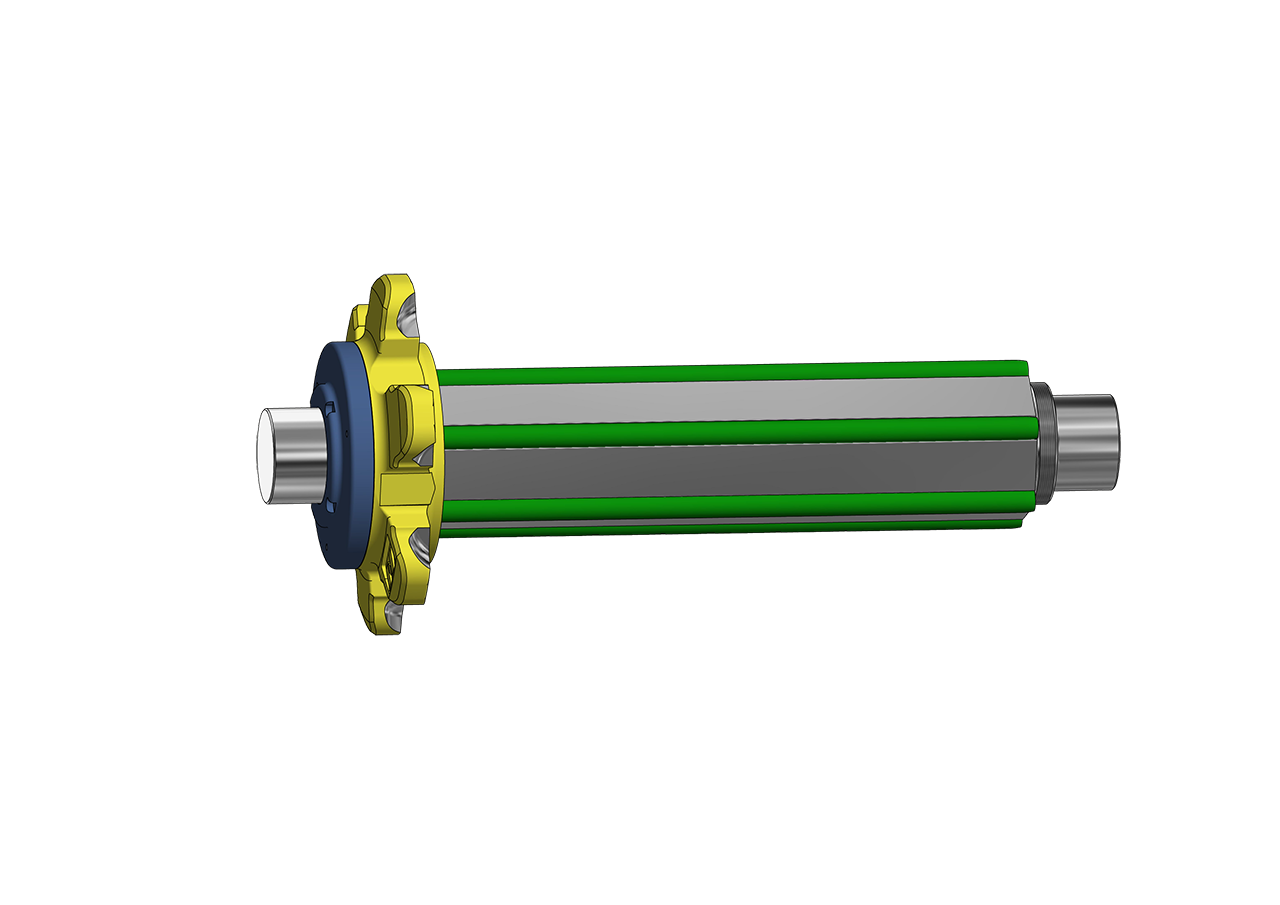

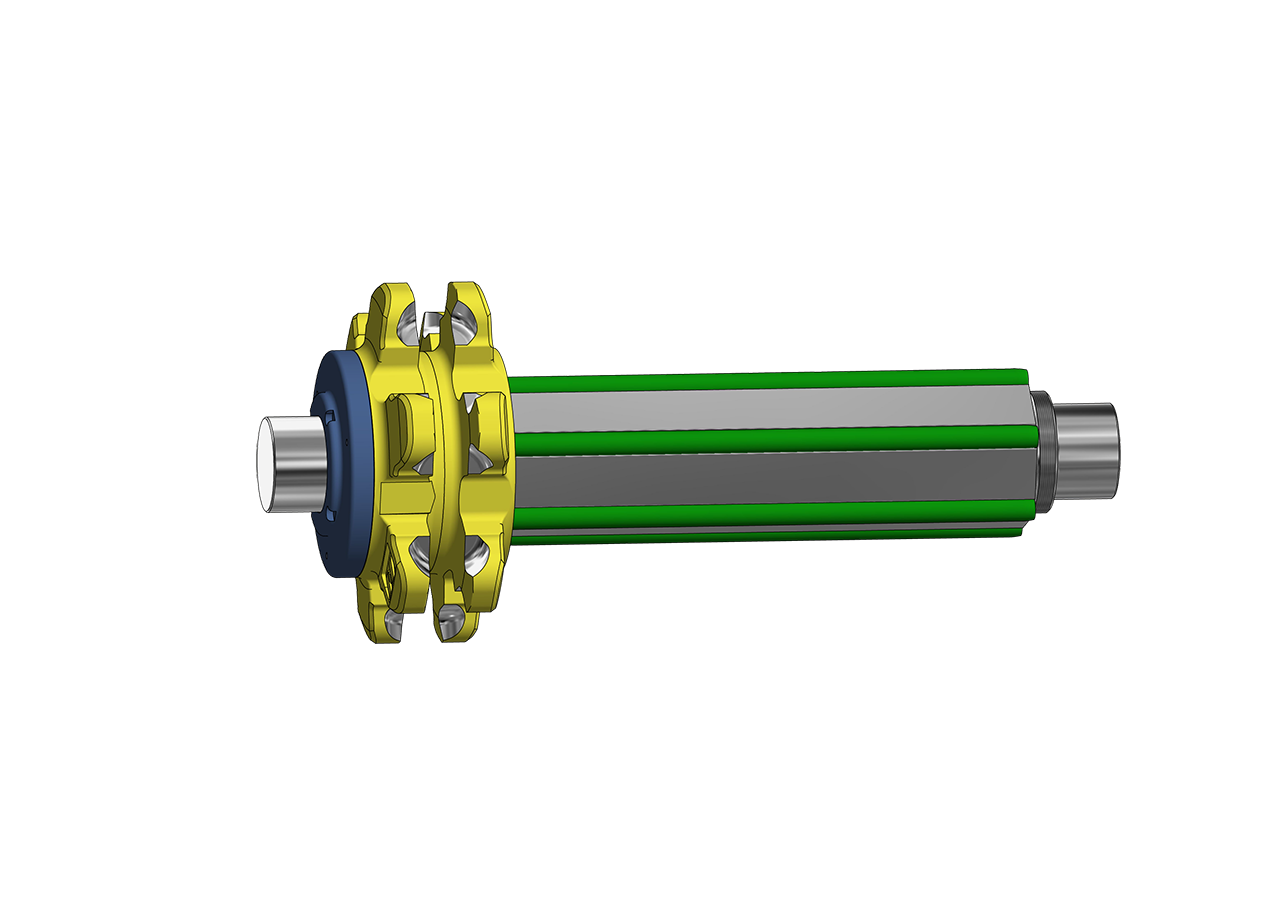

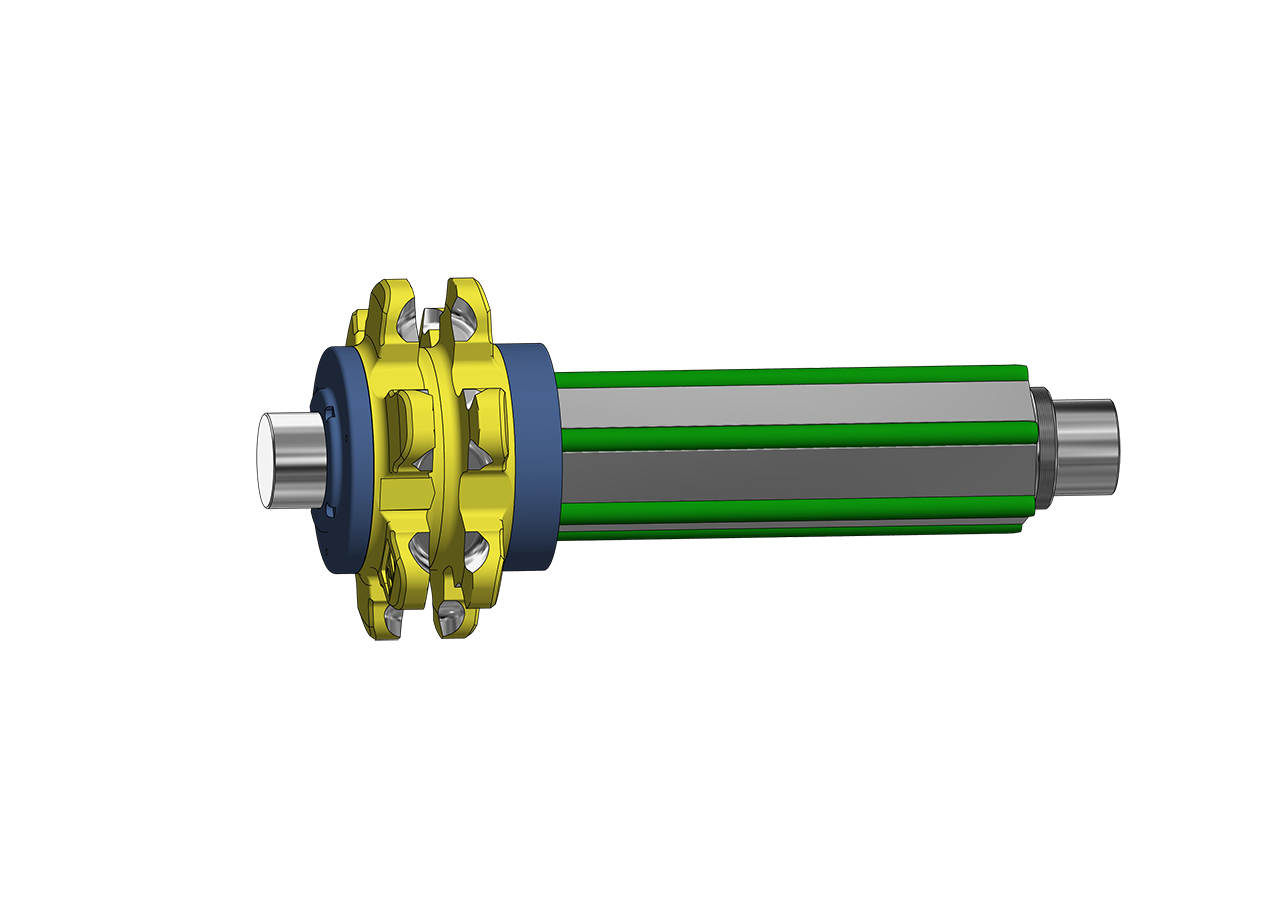

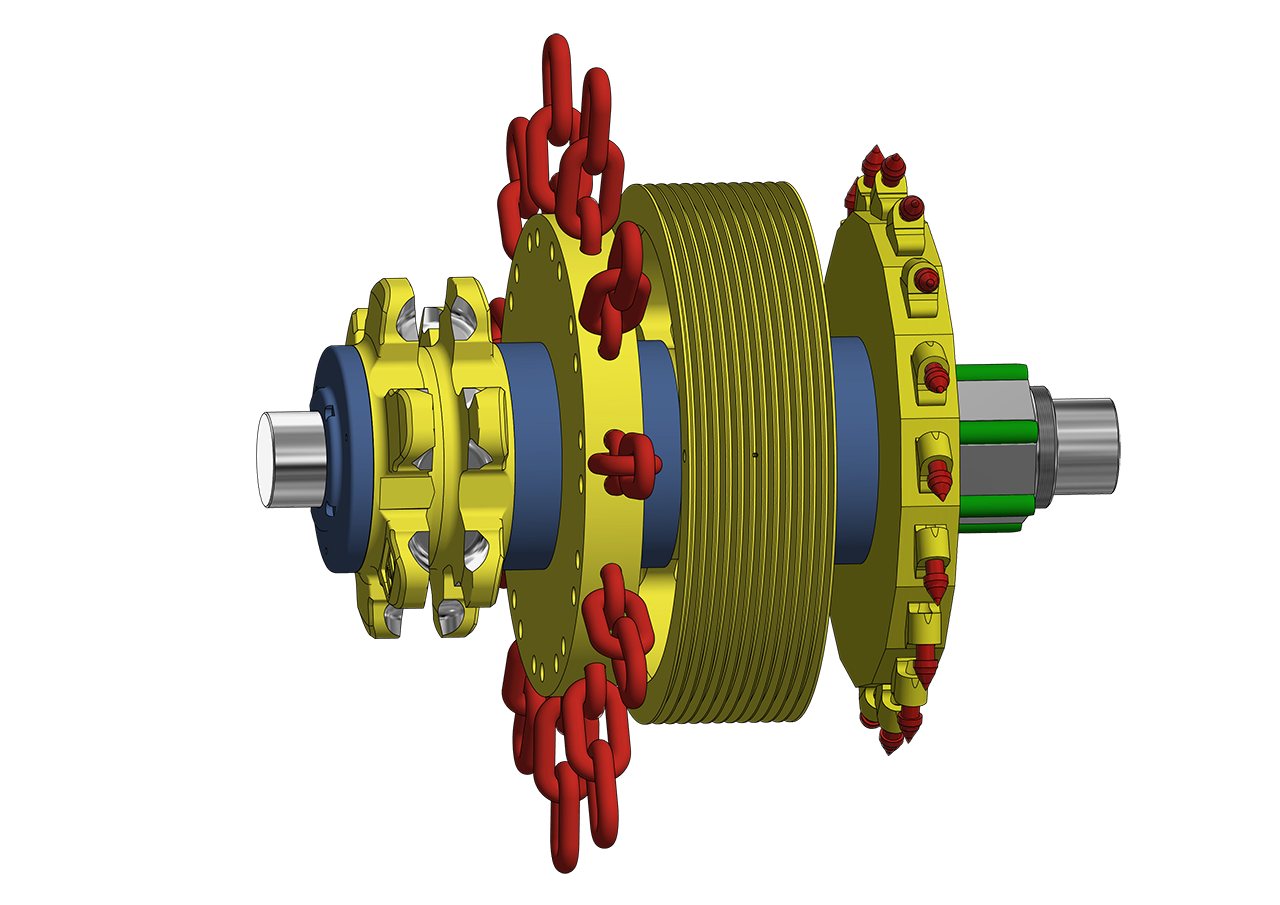

SHAFT-HUB-CONNECTION

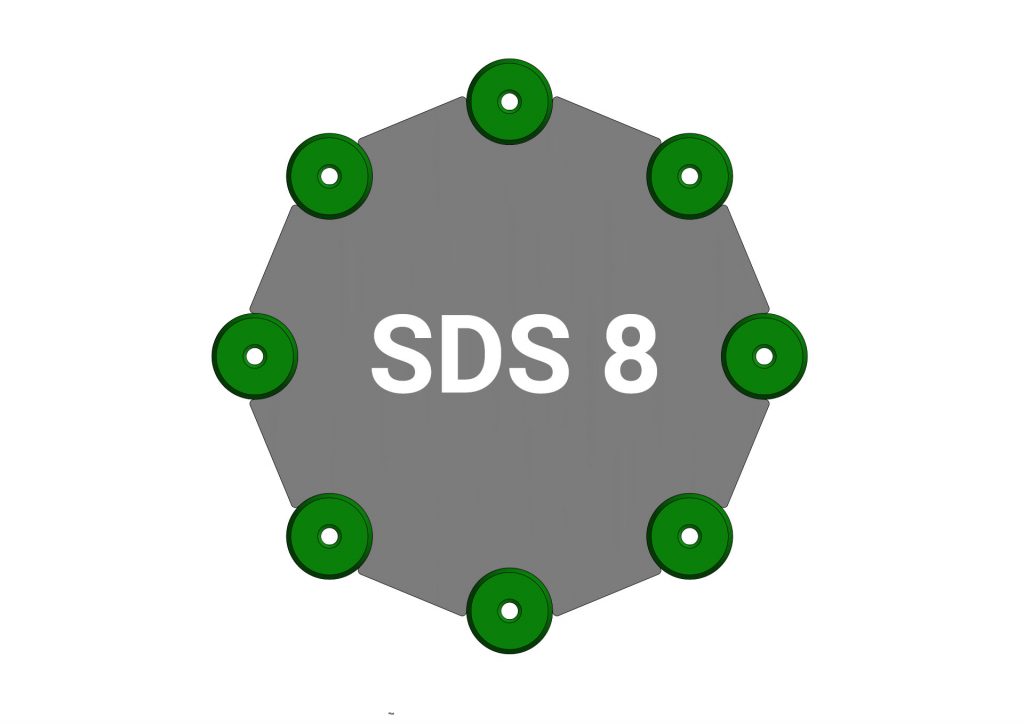

The Shaft with Syndisk-Geometry, the carrier, is made from a high-alloy forged steel, quality tempered to withstand high loads. Moreover, the carrier is double treated in a special process to increase the resistance against abrasion, adhesion and corrosion which also improves the sliding properties for easy installation of the discs. This leads to a high grade of sustainability and reusability. In a longterm, the end user can save money because only worn or damaged discs have to be exchanged and the carrier can be reused.

PRINCIPLE

When full assembled the system increases the torque to the maximum potential of the shaft. In reverse order the friction surface of the shaft is decreased to a minimum which enables sustainable usage of the core component, the shaft, whereas the components which are under direct wear, the discs, can be easily exchanged.

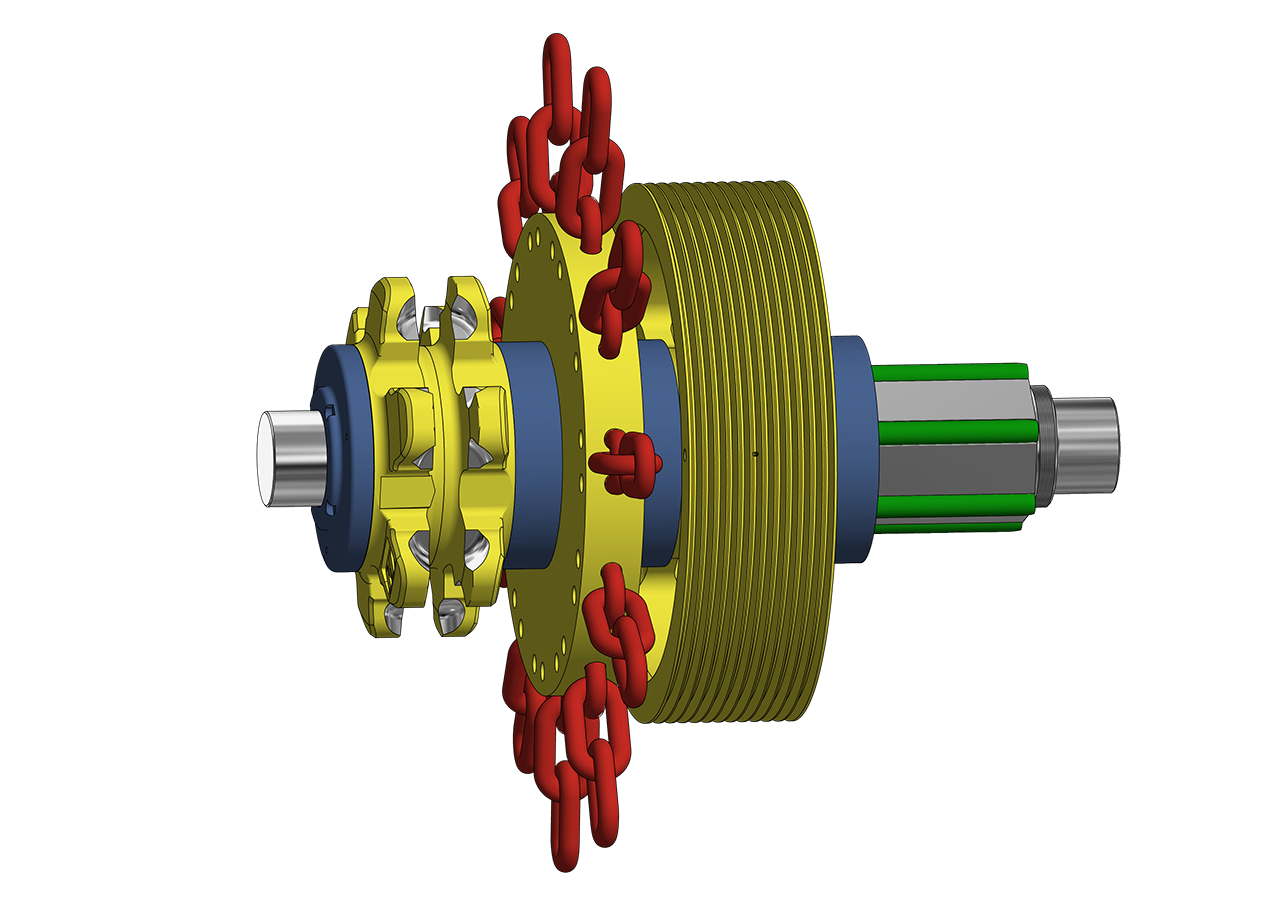

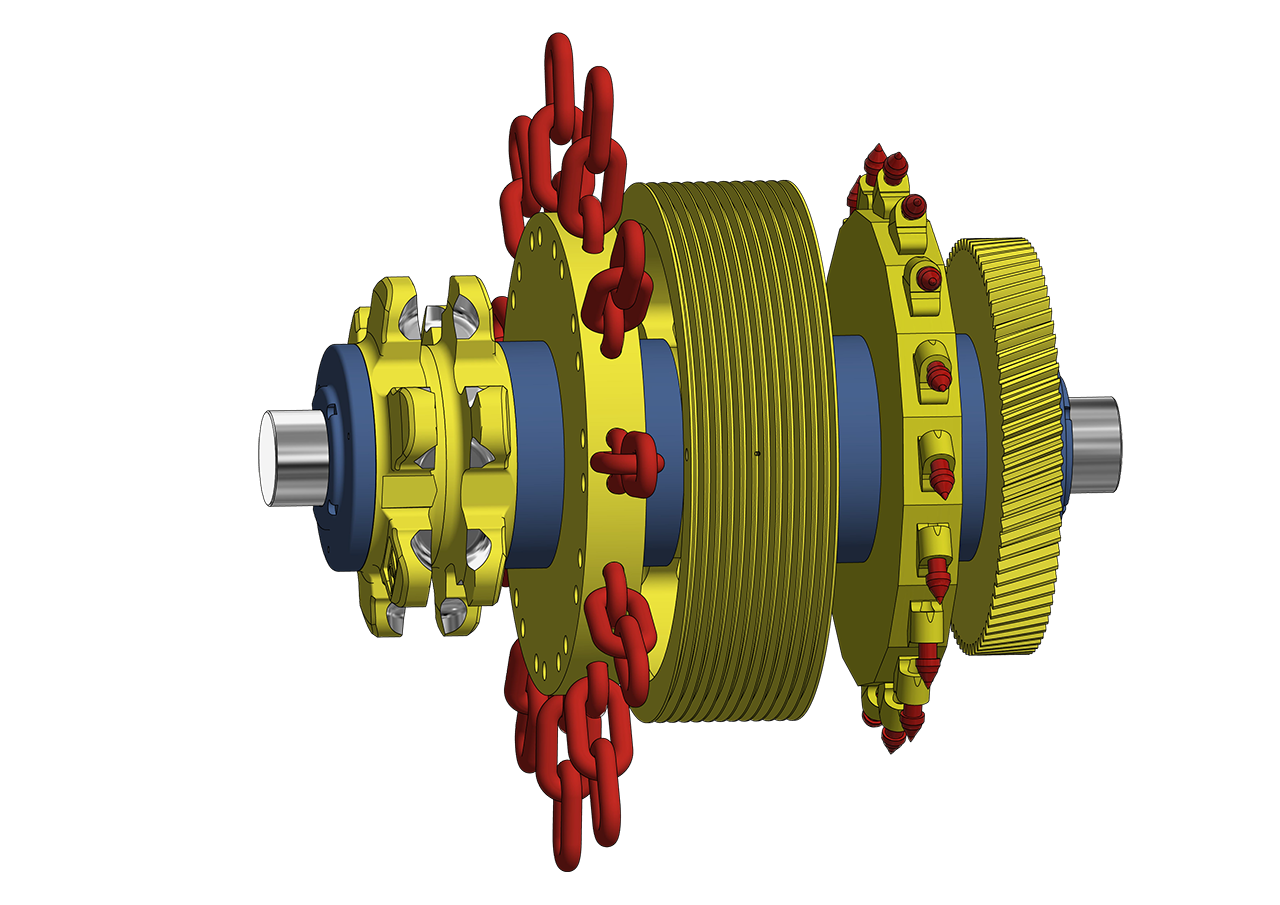

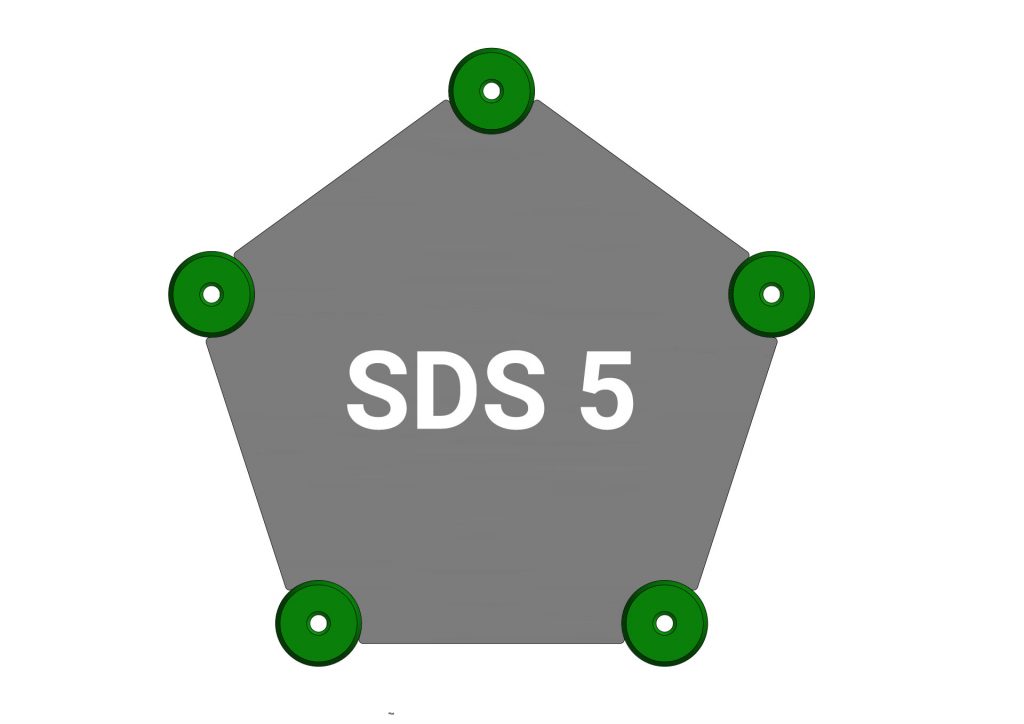

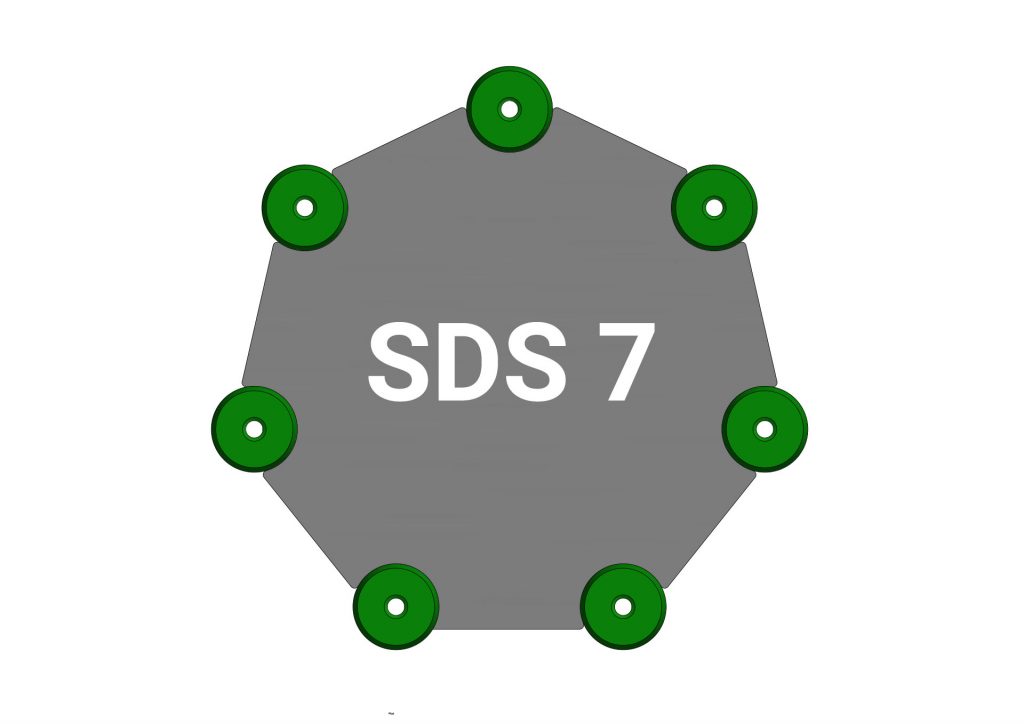

The whole assembly group is sealed against corrosion and is therefore a selfcontained system which can be implemented into nearly every existing overall-system or planned for a new system layout. The N-Force Sprocket and Rotor Disc Series are designed to match the Syndisk-System perfectly and are made for working with high loads. The modular building block system enables various combinations to fulfill the customers multiple tasks.

maximum quality for maximum life.

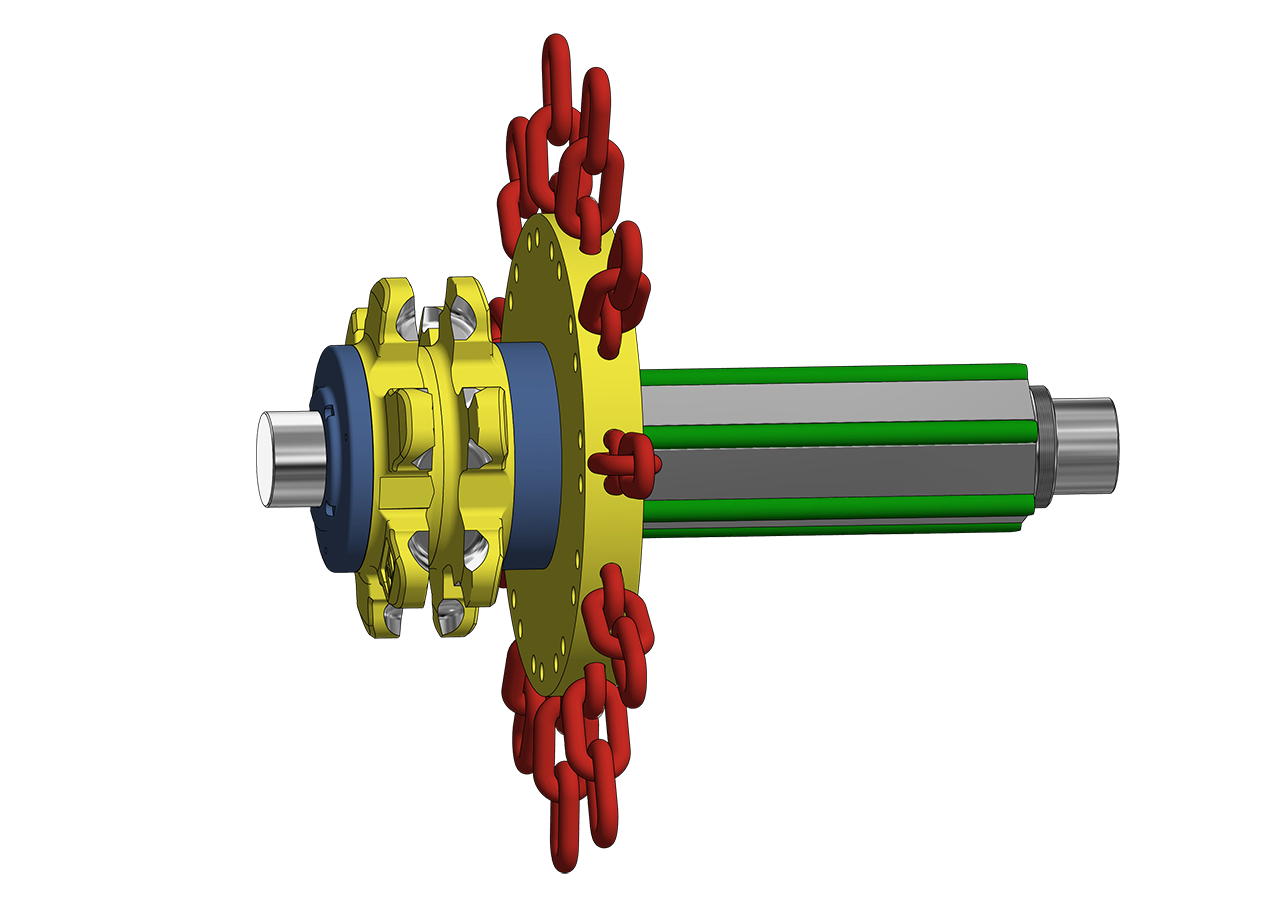

N-FORCE SPROCKET SERIES®

The N-Force Sprocket Disc Series® which is a new way of manufacturing sprockets regarding material and heat treatment is our high end solution for highest requirements and maximum service life. The sprockets have a core hardness of appr. 1200 N/mm²+ and the hardness of the teeth is appr. 63 HRc maximum. Although the hardness is very high the sprocket is still characterized by great toughness which is important. The N-Force Sprocket Series® is available starting with chain size 42mm up to 60+mm.

When using a common sprocket, the whole sprocket has to be exchanged against a new one if only one tooth is broken or heavily damaged. With Syndisk-System, only the affected disc has to be substituted by a new one. Even if a common sprocket is worn asymmetrically (which is the general case) it damages the chain and hast to be exchanged depending on the concrete situation. Opposed to Sprocket Discs on a Syndisk-System the arrangement of the discs on the carrier can be changed without buying new equipment. The customer can easily change the arrangement between the discs, means exchanging the position of slightly worn discs with the position of discs which are more subjected to wear.

Contact Us

Phone

+49 (0) 2304 - 91168 28

Address

Neuhaus Maschinenbau GmbH

Adolph-Kolping-Straße 18

Gewerbegebiet Nattland

58239 Schwerte